Choosing the correct heat treatment process is key to achieving the desired performance in automotive and industrial components. Two commonly used processes — Carburizing and Carbonitriding — seem similar but have distinct advantages depending on the application.

This blog explains both processes in detail, helping manufacturers select the right treatment for gears, shafts, sprockets, and high-stress precision parts.

What is Carburizing?

Carburizing is a process where carbon is diffused into the surface of steel at high temperatures. This creates a hard, wear-resistant case layer, while the core remains tough and impact-resistant.

Best Suited For:

Gears

Camshafts

High-wear rotating components

Precision automotive parts

Key Benefits:

Excellent wear resistance

Hard case depth with strong core

Long component life under repeated load

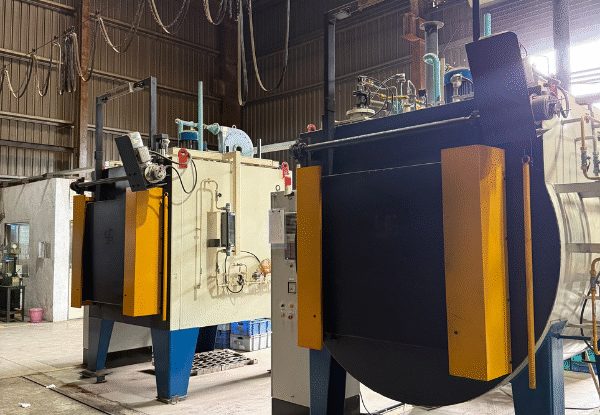

At Alfa Heat Treatment Works, carburizing is carried out in Sealed Quench Furnaces (600 kg batch) to ensure temperature uniformity and stable case hardness.

What is Carbonitriding?

Carbonitriding is similar to carburizing but introduces both carbon and nitrogen into the metal surface. This process enhances fatigue strength and reduces distortion, making it suitable for small or thin components.

Best Suited For:

Small gears

Bushings & pins

High-cycle moving parts

Fasteners

Key Benefits:

Better fatigue resistance

Improved hardness at lower temperature

Lower risk of warping or distortion

Comparison at a Glance

| Feature | Carburizing | Carbonitriding |

|---|---|---|

| Diffusion Elements | Carbon only | Carbon + Nitrogen |

| Case Hardness | Very high | High |

| Distortion Risk | Moderate | Low |

| Ideal Components | Medium/large wear parts | Small / thin high-speed parts |

Why Process Selection Matters

Choosing the wrong process can lead to:

Premature wear

Failure under load

Distortion and rejection

Increased machining rework costs

Selecting the right heat treatment service ensures efficiency, safety, and long-term reliability.

Services Available at Alfa Heat Treatment Works

✔ Carburizing

✔ Carbonitriding

✔ Through Hardening

✔ Stress Relieving & Annealing

✔ Shot Blasting

✔ Metallurgical Analysis & Testing Laboratory

Conclusion

Both carburizing and carbonitriding are essential for modern manufacturing — but the correct selection depends on component design, function, and load conditions.

With advanced furnaces, laboratory testing, and experienced heat treatment engineers, Alfa Heat Treatment Works provides tailored heat treatment job work solutions to meet industry standards and customer performance needs.

📞 Contact Us: 9923207383 | 9850032023

🌐 www.alfaheattreatment.com

Comments (3)

Riva Collins

It’s no secret that the digital industry is booming. From exciting startups to need ghor

global and brands, companies are reaching out.

CaseThemes

It’s no secret that the digital industry is booming. From exciting startups to need ghor global and brands, companies are reaching out.

Oliva Jonson

It’s no secret that the digital industry is booming. From exciting startups to need ghor global and brands, companies are reaching out.